LM-ETK

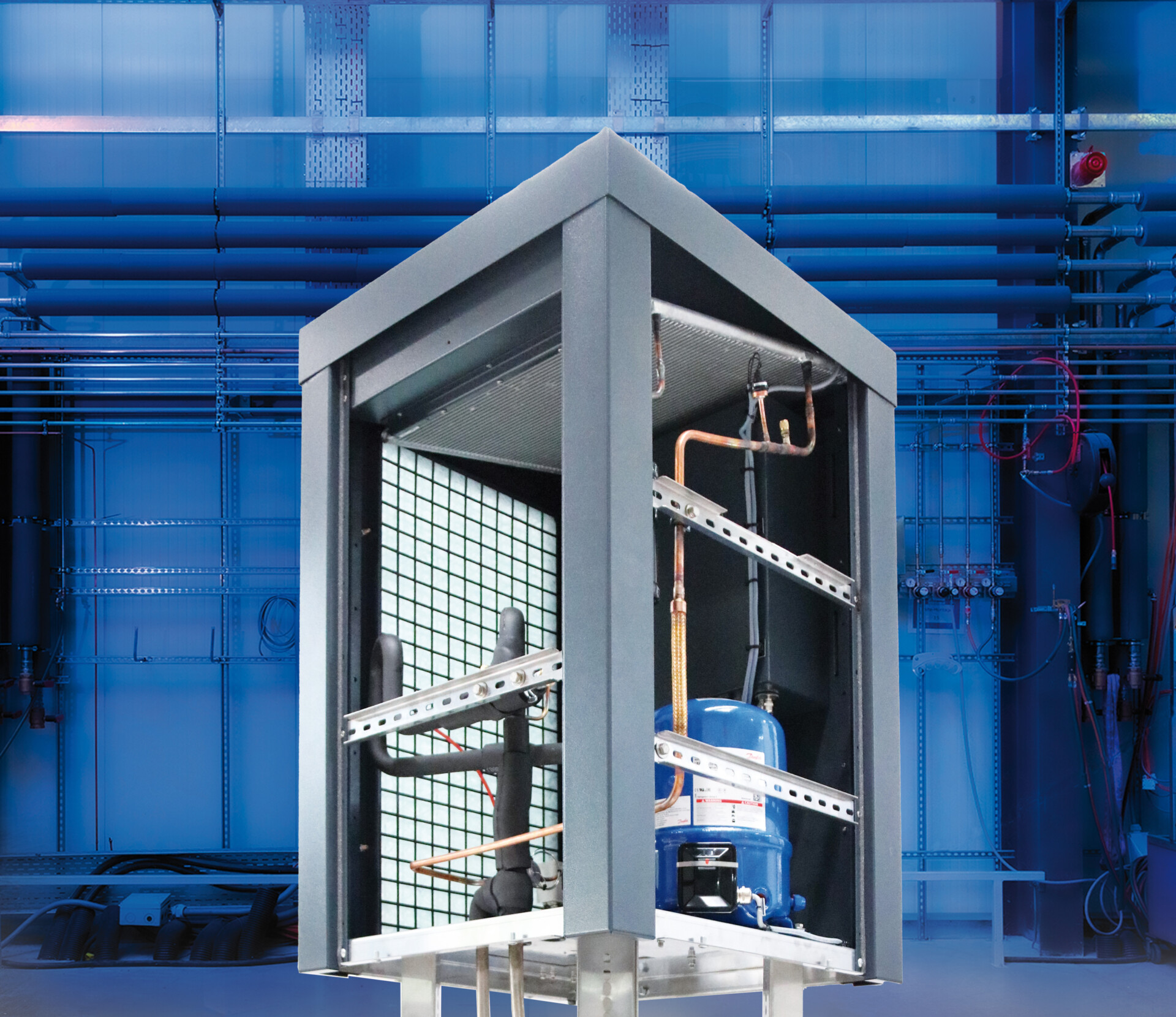

he LM-ETK immersion chiller series offers extremely compact, plug-in compressor cooling units that are ideal for the economical cooling of a diverse range of liquid container processes. Immersion chillers are preferentially used for temperature control of cooling lubricants in filtration and mechanical engineering. The evaporator is immersed directly in a liquid, which is cooled by a cooling process. Optionally, a heater can be installed to heat up the liquid to a suitable temperature in the winter months after the process has stopped. By using innovative technology and future-oriented refrigerants, LM-ETK chillers achieve high energy savings with a short amortization time. Based on a modular unit concept, with cooling capacity classes up to 70 kW, a wide range of configurations can be provided to create units that meet specific customer requirements and applications. By installing a freely programmable controller, the control can also be specifically adapted to customer requirements (e.g. reference control). If cooling water is available, all units can also be designed as water-cooled versions.

Version

Housing and immersion depth can be adapted to the customer’s tank dimensions and media levels.

Installation

At the air inlet—through a filter grille on the back of the cooling unit—there should be a minimum distance of 0.5 m to a wall; at the air outlet—on the top of the unit—there should be a distance of 1–1.5 m to wall and ceiling surfaces. It must also be ensured that neither air flow resistance nor air recirculation occurs.

Refrigerant

For the power classes LM 010 to LM 075 kW, we use the refrigerant R513A as standard; for the power classes LM 092 to LM 310, we use the refrigerant R513A, R513A or alternatively refrigerants with a low GWP in safety class A2L.

Temperature control range

The cooling medium in the tank can be set as standard between +15 °C and +25 °C as required

(optionally up to +40 °C).

Hysteresis and switching frequency

The standard setting for the switching differential is +/-1 K, depending on the model; the size of the customer’s tank may also allow a smaller hysteresis. If a higher temperature accuracy is required, the chillers can be equipped with a hot gas bypass control, enabling 0.1 K control in most cases. For chillers with higher power classes (e.g. >8 kW) and higher temperature accuracy requirements, the use of frequency-controlled compressors instead of hot gas bypass control is recommended. For immersion chillers with a high requirement for control accuracy, working with the customer is necessary to perform an evaluation of the existing tank mixing. Sufficient agitation/mixing in the tank is required to prevent temperature stratification. We achieve this by using agitators or circulating pumps, which allow for better temperature uniformity in the tank.

Cooling medium

The evaporator is made of copper as standard. Depending on the medium, such as mineral oils, we use nickel-plated evaporators to prevent the risk of corrosion damage caused by acids in the medium. Cooling lubricant, water-glycol mixtures, distilled / demineralized water, hydraulic oil or mineral oil according to DIN 51524 T1 and T2 can be used as cooling medium. The cooling medium affects the dimensioning and design of the evaporator.

Ambient temperature

The permissible ambient temperatures are between +15 °C and +42 °C as standard. The performance data refers to and ambient temperature of +32 °C. A power reduction of approximately 2% per 1 K temperature increase occurs between +32 °C and +42 °C.

Protection class

Protection classes IP 44 or IP 54 apply to all sizes.

Paint finish

Our standard paint color is RAL 7035. Our in-house paint shop can provide customized paintwork in any RAL color. For outdoor installation, the base/struts are made of stainless steel and the painted sheet metal parts are coated with a separate primer and additional UV protective paint.

Options

- UL version

- Tank heating

- Agitator

- Immersion pump

- Reference control