We want our customers to be able to rely on our chillers. And that’s precisely why we developed an after sales concept that covers the areas of leak tests, maintenance and warranty extensions as well as LIM (Lahntechnik Information Monitoring) and remote maintenance.

Everything to ensure the longevity of your systems

1. Leak tests

We are aware of our responsibility for the environment. Cooling units often contain greenhouse gases that mustn’t be released into the atmosphere. The EU Regulation 517/2014 governing fluorinated greenhouse gases is authoritative for us in this respect. As a manufacturer of cooling systems, this Regulation obliges Lahntechnik GmbH to have regular leak tests carried out by specialists. There is a legal obligation to keep documentation, and the corresponding operating manuals are subject to a retention obligation of five years.

Our service team will of course take care of these tasks, too—which incidentally is the case regardless of the legally prescribed warranty.

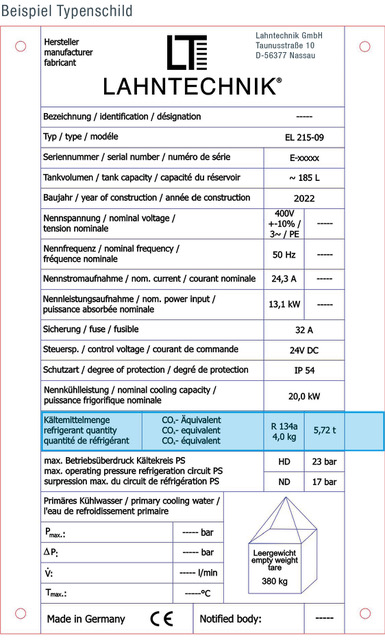

Here’s some more specialist information we’d like to share with you: The new version of the F Gas Regulation no longer refers directly to the refrigerant charge when classifying the periodic leakage checks. The groups are classified according to the mass of CO2 equivalents. The CO2 equivalent of a refrigerant is calculated by multiplying the charge by the GWP (Global Warming Potential). The GWP refers to the global warming potential of a greenhouse gas in relation to carbon dioxide (CO2).

For example:

1 kg R134a has a CO2 equivalent of 1.43 t

1 kg R404A has a CO2 equivalent of 3.92 t.

| Fill quantity CO2 equivalent | Frequency without leakage detection system | Frequency with leakage detection system |

| a) From 5 and under 50 tonnes | Every 12 months | Every 24 months |

| b) From 50 and under 500 tonnes | Every 6 months | Every 12 months |

| c) From 500 tonnes | Every 3 months | Every 6 months |

Information on the necessity of a leak test can be found on the type plate under CO2 equivalent and in the unit’s operating instructions.

2. Maintenance

Saving on maintenance means underperformance and jeopardizing the stability of production. This is exactly what Lahntechnik’s maintenance concepts are designed for.

Scope of services for maintenance in accordance with the German Engineering Federation (VDMA)

- Visual inspection

- Leakage checks of the cooling system(s) according to Regulation (EU) No 517/2014

- Check of the entire cooling circuit and temperature measurements

- Check of the functions of all switching and control components including electrical connections

- Check of the current consumption of the main components

- Testing of the medium circuit

Maintenance documentation

Maintenance report

Measurement protocol

Recommendations for preventative actions to avert failures

This is all you have to do:

Take a photo of the type plate and email it together with a short description of your issue to our service team at: service@lahntechnik.de

We will send you your individual maintenance quotation shortly afterwards and contact you personally to arrange an

appointment.

Maintenance contracts

We’ll do the work for you!

Our maintenance contracts mean you don’t have to worry about having your equipment looked after:

Our experts will contact you regularly and in good time to arrange an appointment! Allow us to tell you all about the preferential rates and discounts on components when we meet in person. The most important thing to be aware of is that preventive maintenance extends the service life of your system!

3. Warranty extensions

Stay on the safe side and save yourself unexpected costs after the statutory manufacturer’s warranty expires.

With the Lahntechnik warranty extension!

- You can purchase the warranty extension when ordering new machines.

- It is valid from the date of acceptance of the chiller, but no later than three months after delivery. It also applies to chillers that are already in use, if regular maintenance and leak tests can be supported by the operating manual.

- Of course, damage caused by improper handling is excluded, as are maintenance and wear parts and operating materials.

Guaranteed safe—safety guaranteed

The warranty extension period can be selected according to your needs.

If you have any queries at all, our service team will be happy to help and advise you.

So get in touch with us and benefit from your chiller having maximum operational safety!

If you have any queries, just get in touch with us and a contact person will get back to you as soon as possible!

4. LIM and remote maintenance—truly up to speed!

LIM—Lahntechnik Information Monitoring is our system that allows us to retrieve your chiller’s real-time data. For the safety of your systems, it ensures optimum operation, using VPN tunnels and offering a high level of cybersecurity. The LIM enables you to control all relevant parameters from your computer, tablet or smartphone. This means that potential for optimization can be quickly identified!

Remote maintenance is based on a remote diagnosis that can be carried out at short notice by our service team at any time via a gateway. Faults are detected quickly and can be rectified just as fast. All for the best machine availability—and not least in terms of cost efficiency! The LIM is definitely the best solution! The remote maintenance packages are always tailored to your individual and specific needs with maximum transparency!

Please get in touch with our service team:

Service-hotline: +49 2604 9 555-111

Email: service@lahntechnik.de