Preparation and cooling of process media

Preparation and cooling of process media

Process media are an integral part of industrial manufacturing with CNC machine tools. Since the process media are directly introduced into the machining process to enable effective cooling, they become contaminated. Grinding dust, metal chips and tool debris accumulate in the process media.

Various filtration systems can be used to remove the impurities from the cooling medium, depending on the application and degree of cleaning.

Let us work with you to develop a customized solution.

Customized applications:

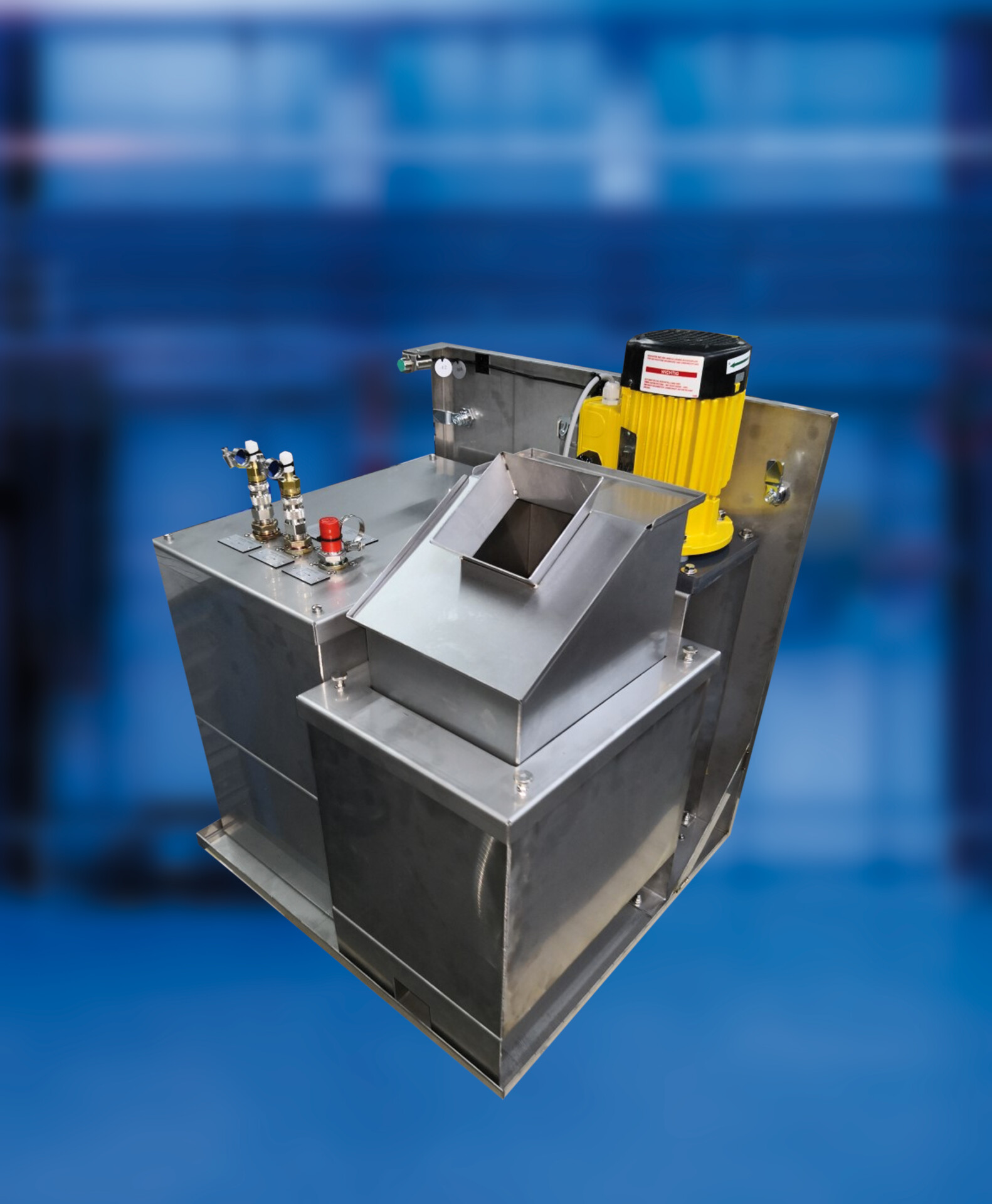

Poliermittelkühlung und -filtration

Poliermittelkühler werden zum Temperieren und Fördern von Suspensionen eingesetzt. Diese können an Poliermaschinen und anderen Maschinen eingesetzt werden, welche eine exakt temperierte Medienzuführung benötigen.

Die dem Bearbeitungsprozess zugefügte Prozessflüssigkeit dient zur Oberflächenbearbeitung wie Schleifen, Polieren, Veredelung. Je nach Grad der Material-Abtragung wird die Filtrations- und Abscheidetechnik gewählt.

Ergänzend zur Filtration/Abscheidung wird die Wärmeenergie, welche durch den Bearbeitungsprozess auf das Poliermittel einwirkt, abgeführt und auf der idealen Prozesstemperatur gehalten.Polishing media cooling and filtration

Polishing medium chillers are used for tempering and conveying suspensions. They can be used on polishing machines and other machines that require a media supply at an exact temperature.

The process fluid added to the machining process is used for surface treatment such as grinding, polishing, finishing. Filtration and separation technology is selected depending on the extent of material removal.

In addition to filtration/separation, the heat energy, which acts on the polishing medium through the machining process, is dissipated and kept at the ideal process temperature.Cooling lubricant filtration

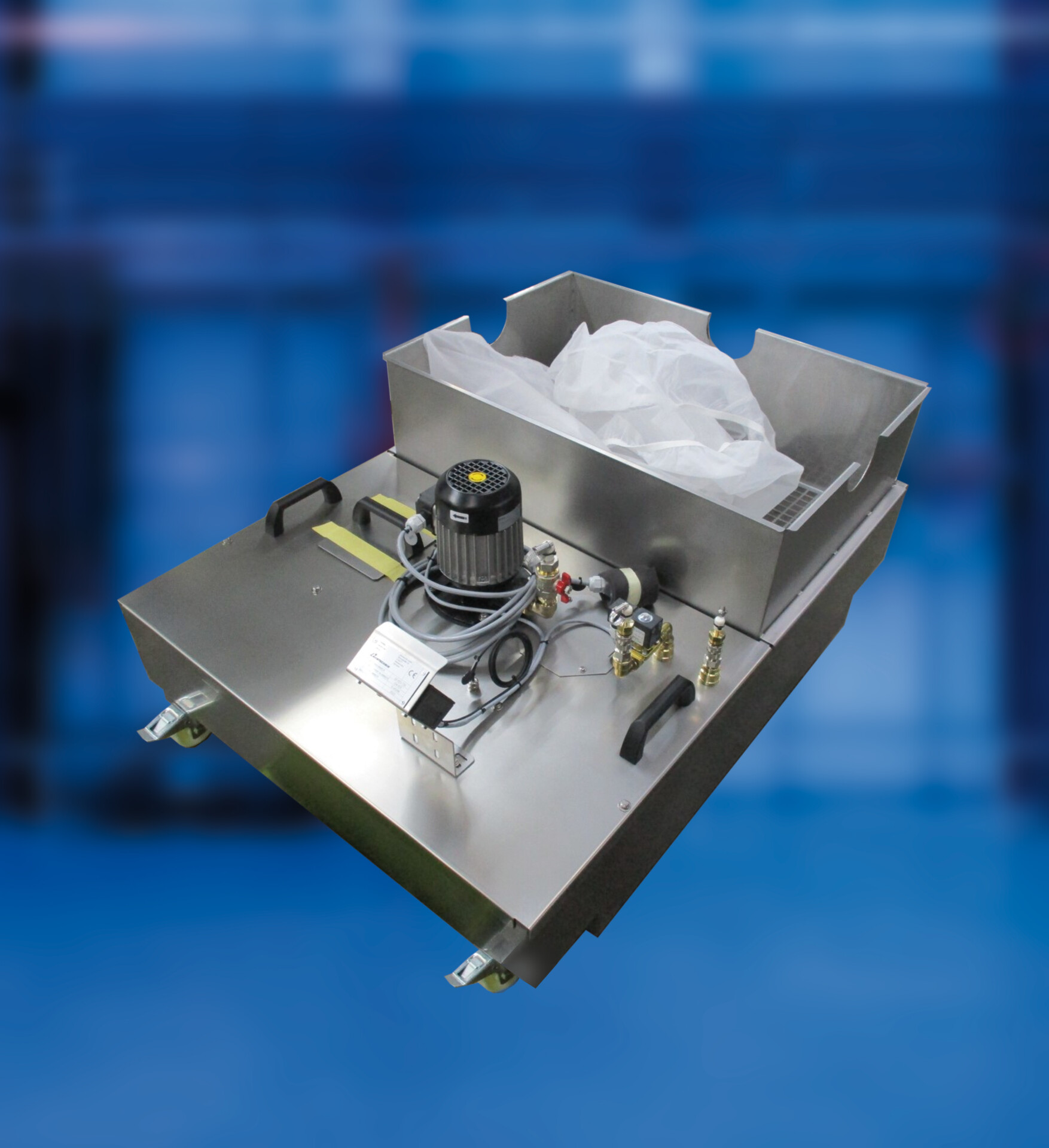

Cooling lubricant filtration systems are used to filter and temper cooling lubricants during a grinding process.

A washable or replaceable screen bag is used for filtration.

The systems are suitable for connection to grinding and milling machines, such as those used for processing lenses for glasses.

Centrifuges

During centrifuging, the solid contaminants are separated from the liquid coolant lubricant by the centrifugal forces, which are conveyed during machining. In contrast to filter / screen systems, separation takes place without wear and tear and is resource-saving The service life (quality) of the process fluid is also significantly increased.