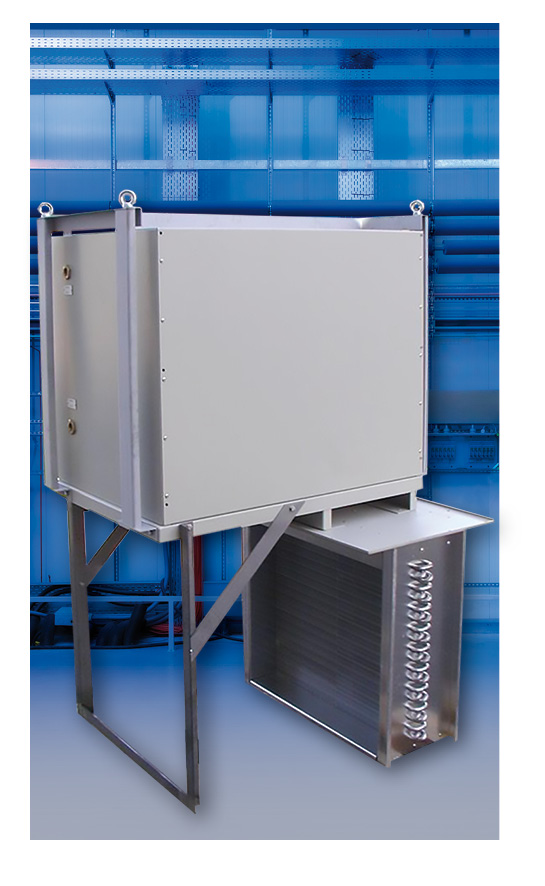

DV SERIES

Process air cooler with cooling circuitDESIGNS FOR YOUR SPECIFIC

REQUIREMENTS

Variable temperature control

There are two variants available for high precision temperature control: Fixed-value temperature control for a constant supply air temperature or differential control with reference-guided supply air temperature.

A microprocessor-controlled temperature control unit regulates the supply air temperature and ensures that the cooling system output is adjusted.

Temperature deviations are signaled via a parameterizable alarm output. Setpoint and actual temperature

are visualized on the control cabinet. The setpoint can be changed by the customer.

During commissioning, the system can be optimized to the customer’s conditions on site.

Each DV unit is wired ready for connection—including the control cabinet. Other interfaces can

be provided on customer request.

The modular design allows adaptation to different installation situations. This means that we can provide swift customized solutions to meet any customer requirement—naturally, in all the standard voltages and mains frequencies as well as in accordance with current electrical standards.

DV coolers undergo extensive functional and performance tests and are thoroughly tested to their limits to guarantee the specified performance.

Product features

- High-performance evaporator with copper tubes and pressed-on aluminum fins

- High-performance condenser with axial fan in air-cooled design

- Stainless steel plate heat exchanger with cooling water controller in water-cooled version

- Fully or semi-hermetic compressors, 100 % suction gas cooled

- Thermostatic or electronic expansion valves

- Microprocessor-controlled temperature control unit

- Automatic power control

- Control accuracy ±1 K

- Condensing pressure control

- Pre wired control cabinet in industry standard design

- Signal exchange via Harting connector for external release, operating and fault indication

Customized design, constructions in modular design

DV coolers are optionally available with evaporator housing. Our DV series evaporators are made of copper tubes with aluminum fins. Optionally, the heat exchangers are available in stainless steel versions V2A or V4A.

In variants with evaporator housing, any condensation water that forms is drained off via an open drain. The installation of a droplet separator depends on the technical specifications.

Industries and applications

- Air conditioning

- Charging of cooling zones for workpieces in the metal working industry

- Manufacturing processes for syrups and chocolate in the food industry

Options at a glance

- High-performance evaporators in various material combinations, e.g. stainless steel tubes (V2A, V4A) with pressed-on epoxy resin coated aluminum fins

- Special voltages and special standards such as UL, CSA

- Control accuracy ±0.5 K

- Reference control

- Outdoor installation

- Evaporator housing

- Housing with customized paintwork or in stainless steel

- Fan speed control

- ASI / Profibus connection, Ethernet connections

- PLC control systems

- Power-controlled compressors for energy-efficient output adjustment

- Control cabinet with flexible installation

- External condenser / external condensing unit

Advantages at a glance

- Planning, project scheduling, optimization and production from one source

- Electronic integration into central control systems

- Instruction and training courses for operators

- Using reputable brand manufacturers enables fast procurement of spare parts.

- 24-hour hotline and service network

- 5 years’ warranty with a maintenance contract